Product Detail

1.Product Name

PIR MOTION SENSOR “PaPIRs”

WL series・Horizontally wide detection type (2μA / Digital output )

2.Model Number

Lens Color | Model Number |

White | EKMB1205111 |

Black | EKMB1205112 |

Pearl White | EKMB1205113 |

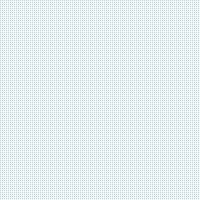

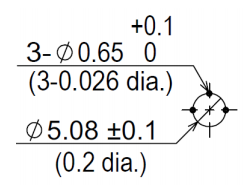

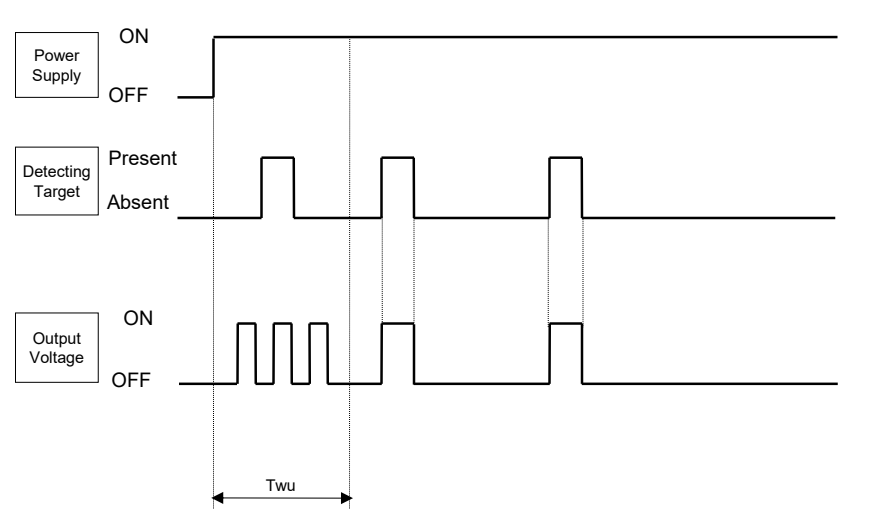

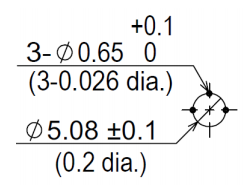

3.Dimensions

4.Characteristics

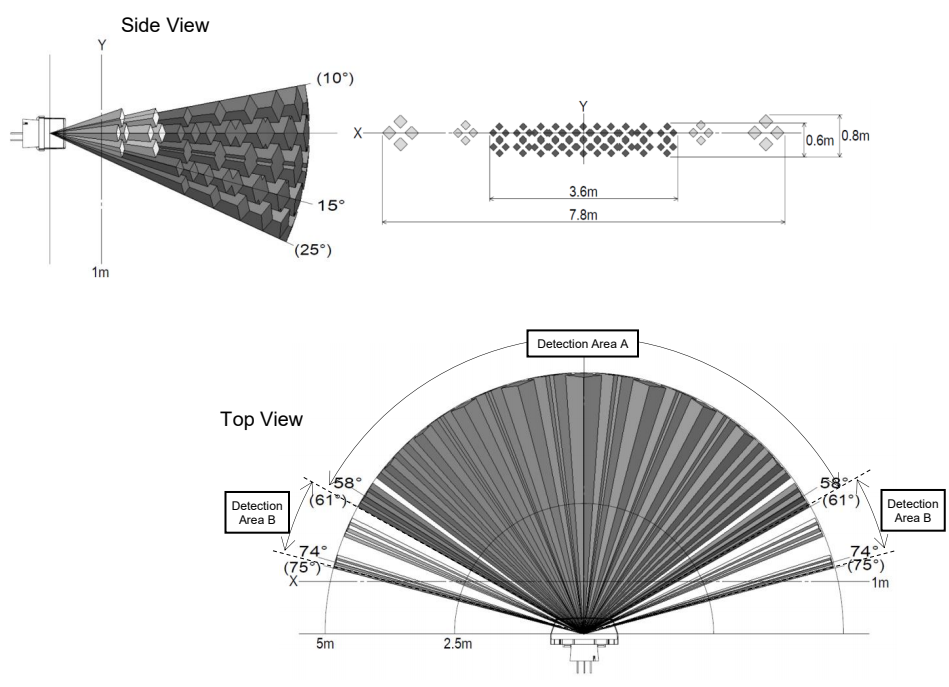

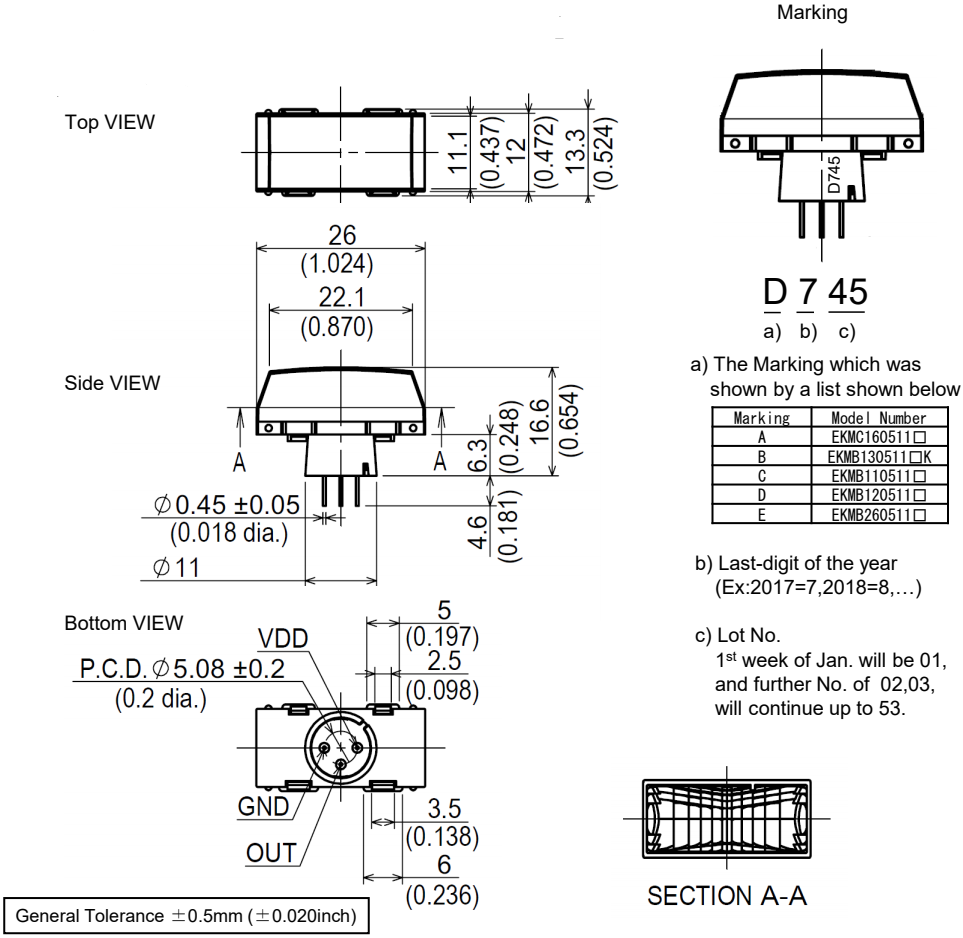

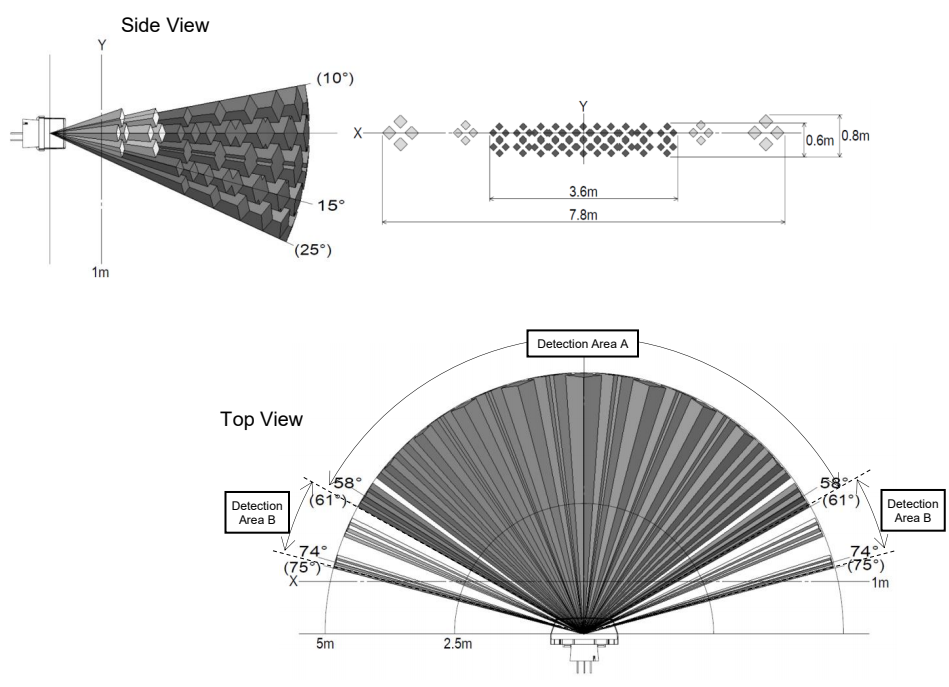

4-1 Detection Performance (Detection Area A)

Conditions for measuring: Ambient temperature=25℃(77°F) Operating voltage=3VDC

| Temperature difference | Value | Conditions concerning the target |

(Note1) Detection Range | 4℃(7.2°F) | Max 5m | 1.Movement speed: 1.0m/s 2.Target concept is human body (Object size:Around 700×250mm) |

Note1:Depending on the temperature difference between the target and the surroundings, detection range will change.

| Value | Notes |

Detection Area | Horizontal | 122°(±61°) | Refer to the section 4-6. |

Vertical |

|

Detection zones | 88 |

4-2 Detection Performance (Detection Area B)

Conditions for measuring: Ambient temperature=25℃(77°F) Operating voltage=3VDC

| Temperature difference | Value | Conditions concerning the target |

(Note1) Detection Range | 8℃(14.4°F) | Max 5m | 1.Movement speed: 1.0m/s 2.Target concept is human body (Object size:Around 700×250mm) |

Note1:Depending on the temperature difference between the target and the surroundings, detection range will change.

| Value | Notes |

Detection Area | Horizontal | 150°(±75°) | Refer to the section 4-6. (Ditection Area A is not included.) |

Vertical | 20°(±10°) |

Detection zones | 16 |

4-3 Maximum Rated Values

| Value | Unit |

Power Supply Voltage | -0.3~4.5 | VDC |

Usable Ambient Temperature | -20~+60℃ (-4~+140°F) Do not use in a freezing or condensation environment |

|

Storage Temperature | -20~+70℃ (-4~+158°F) |

|

4-4 Electrical Characteristics

Conditions for Measuring: Ambient temperature:25℃(77°F)

| Symbol | Min | Avg. | Max | Unit | Special mention |

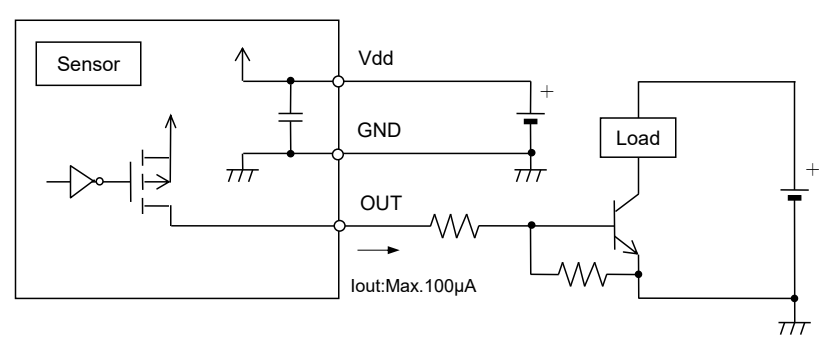

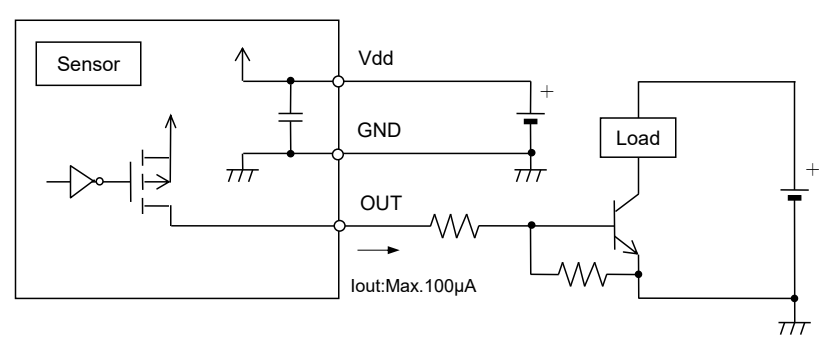

Operating Voltage | Vdd | 2.3 | - | 4.0 | VDC | - |

Electrical Current Consumption | Iw | - | 1.9 | 3.0 | μA | Iout=0 |

Output Current | Iout | - | - | 100 | μA | Vout≧Vdd-0.5 |

Output Voltage | Vout | Vdd-0.5 | - | - | VDC | - |

Circuit Stability Time (when voltage is applied) | Twu | - | 25 | 210 | s | - |

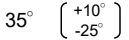

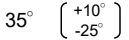

4-4 Timing Chart

【Durations】

Twu:Circuit Stability Time: About 25s. (typ.)

During this stage, the output’s status is undefined (ON/OFF) and detection is therefore not guaranteed.

4-6 Detection Area

4-7 Wiring Diagram

5. Safety Precautions

Head the following precautions to prevent injury or accidents.

1) Do not use these sensors under any circumstance in which the range of their ratings, environment conditions or other specifications are exceeded.

Using the sensors in any way which causes their specifications to be exceeded may generate abnormally high levels of heat, emit smoke, etc., resulting in damage to the circuitry and possibly causing an accident.

2) Our company is committed to making products of the highest quality and reliability.

Nevertheless, all electrical components are subject to natural deterioration, and durability of a product will depend on the operating environment and conditions of use. Continued use after such deterioration could lead to overheating, smoke or fire. Always use the product in conjunction with proper fire-prevention, safety and maintenance measures to avoid accidents, reduction in product life expectancy or break-down.

3) Before connecting, check the pin layout by referring to the connector wiring diagram, specifications diagram, etc., to verify that the connector is connected properly.

Mistakes made in connection may cause unforeseen problems in operation, generate abnormally high levels of heat, emit smoke, etc., resulting in damage to the circuitry.

4) Do not use any motion sensor which has been disassembled or remodeled.

5) Failure modes of sensors include short-circuiting, open-circuiting and temperature rises.

If this sensor is to be used in equipment where safety is a prime consideration, examine the possible effects of these failures on the equipment concerned, and ensure safety by providing protection circuits or protection devices.

Example :

・Safety equipments and devices

・Traffic signals

・Burglar and disaster prevention

6.Operating Precautions

6-1 Basic Principles

PaPIRs is a pyroelectric infrared sensor that detects variations in infrared rays.

However, it may not detect in the following cases: lack of movement, no temperature change in the heat source. Besides, it could also detect the presence of heat sources other than a human body.

Efficiency and reliability of the system may vary depending on actual operating conditions:

1) Detecting heat sources other than the human body, such as:

a) small animals entering the detection area

b) When a heat source for example sun light, incandescent lamp, car headlights etc, or strong light beam hit the sensor regardless inside or outside the detection area.

c) Sudden temperature change inside or around the detection area caused by hot or cold wind from HVAC, or vapor from the humidifier, etc.

2) Difficulty in sensing the heat source

a) Glass, acrylic or similar materials standing between the target and the sensor may not allow a correct transmission of infrared rays,

b) Non-movement or quick movements of the heat source inside the detection area.

(Please refer to 4-1 for details about movement speed.)

3) Expansion of the detection area

In case of considerable difference in the ambient temperature and the human body temperature, detection area may be wider apart from the configured detection area.

4) Malfunction / Detection error

Unnecessary detection signal might be outputted, on rare occasions, come from sudden outbreak output due to the nature of pyro-electric element. When the application does not accept such condition strictly, please implement the countermeasure by introducing pulse count circuit etc.

6-2 Optimal Operating Environment Conditions

1) Temperature : Please refer to the maximum rated values of 4-2.

2) Humidity Degree :15~85% Rh (Avoid condensation or freezing of this product)

3) Pressure : 86~106kPa

4) Overheating, oscillations, shocks can cause the sensor to malfunction.

5) This sensor is not waterproof or dustproof. Avoid use in environments subject to excessive moisture, condensation, frost, containing salt air or dust.

6) Avoid use in environments with corrosive gases.

6-3 Handling Cautions

1) Do not solder with a soldering iron above 350℃(662°F), or for more than 3 seconds.

This sensor should be hand soldered.

2) To maintain stability of the product, always mount on a printed circuit board.

3) Do not use liquids to wash the sensor. If washing fluid gets through the lens, it can reduce performance.

4) Do not use a sensor after it fell on the ground.

5) The sensor may be damaged by ±200 volts of static electricity. Avoid direct hand contact with the pins and be very careful when operating the product.

6) When wiring the product, always use shielded cables and minimize the wiring length to prevent noise disturbances.

7) The inner circuit board could be destroyed by a voltage surge. Use of surge absorption elements is highly recommended.

Surge resistance : below the power supply voltage value indicated in the maximum rated values section.

8) Please use a stabilized power supply. Power supply noise can cause operating errors.

Noise resistance : ±20V or less (Square waves with a width of 50ns or 1μs)

To reduce the effect of power supply noise, install a capacitor on the sensor’s power supply pin.

9) Operating errors can be caused by noise from static electricity, lightning, cell phone, amateur radio, broadcasting offices etc…

10) Detection performance can be reduced by dirt on the lens, please be careful.

11) The lens is made of soft materials (Polyethylene). Please avoid adding weight or impacts that might change its shape, causing operating errors or reduced performance.

12) Operating “temperatures” and “humidity level” are suggested to prolong usage. However, they do not guarantee durability or environmental resistance. Generally, high temperatures or high humidity levels will accelerate the deterioration of electrical components. Please consider both the planned usage and environment to determine the expected reliability and length of life of the product.

13) Do not attempt to clean this product with any detergent or solvent, such as benzene or alcohol, as these can cause shape or color alterations.

14) Avoid storage in high, low temperature or liquid environments. As well, avoid storage in environments containing corrosive gas, dust, salty air etc. It could cause performance deterioration and the sensor’s main part or the metallic connectors could be damaged.

15) Storage conditions

Temperature: +5 ~ +40℃ (+41 ~ +104°F)

Humidity: 30 ~ 75%

Please use within 1 year after products delivery.

7.When Designing Your Product

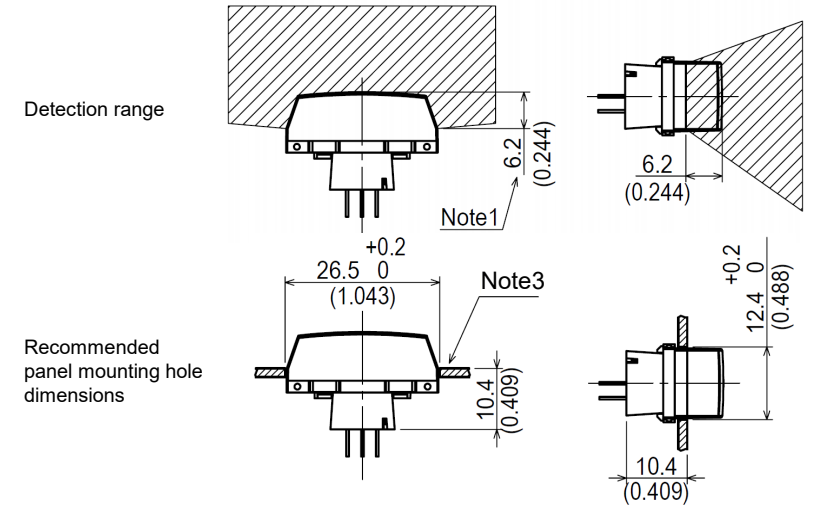

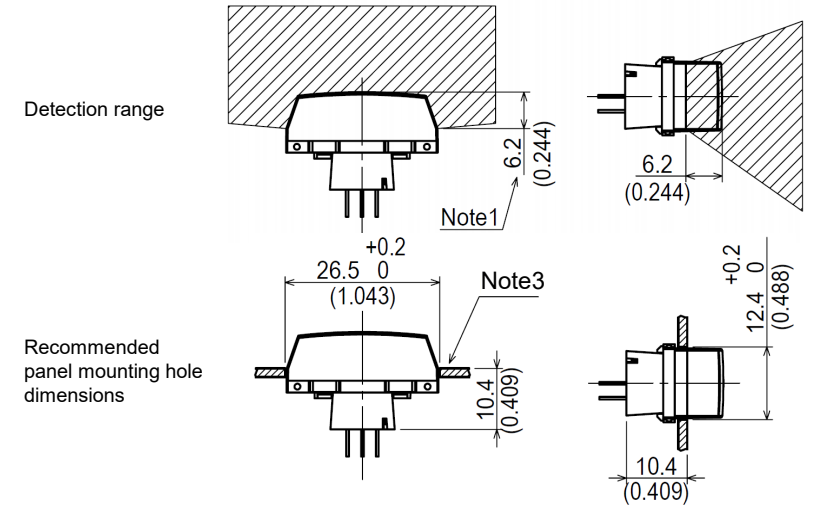

7-1 Using Detection Area A and B

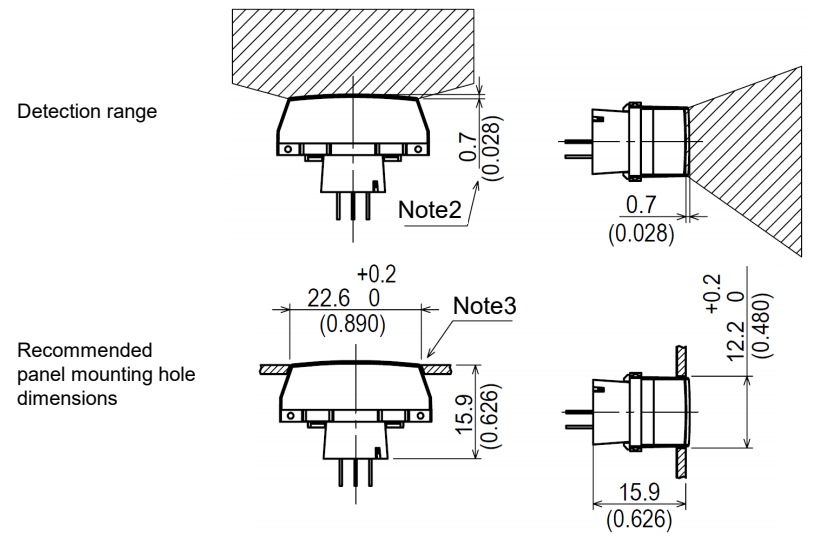

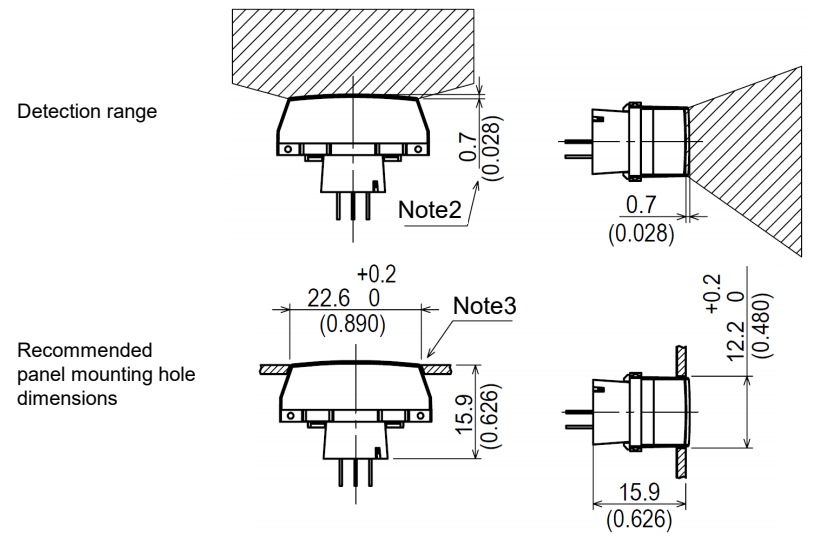

7-2 Using Detection Area A only

Note1 : In order to ensure proper detection,install it with the lens exposed at least 6.2mm.(0.244inch)

Note2 : In order to ensure proper detection,install it with the lens exposed at least 0.7mm.(0.028inch)

Note3 : As for panel mounting hole,tapering or making a large size hole should be done.

7-3 Recommended PCB Pattern Diagram

8.Special Notice

As improvements are continually being made, the specifications or design of this product are subject to change without notice.

Please strictly follow the “Safety Precautions” and “Operating Precautions” on the specifications sheet.

Normal functioning cannot be expected if used in environments or conditions other than those specified above.

We are deeply committed to providing the highest quality control for this product.

Nevertheless:

1) For issues not addressed above, we invite you to share your suggestions, or details about your company’s usage conditions, installation, specifications, needs of end users, and applications for this sensor.

2) To reduce the risk of harm caused by product failure to human life or assets, this product should always be used in conjunction with other safety measures, such as protective circuitry, double layered circuit boards, etc., and used within the guaranteed performance, efficiency or special characteristics values stated in the specification sheet.

3) This product is warranted for a period of one year, from date of delivery, applicable only if the product is used in accordance with the precautions mentioned above and the specifications sheet.

We will replace or repair at the delivery location any malfunctioning or defective part or entire product if such defect or malfunction is caused by us.

However, the above warranty shall be void in the following circumstances:

a) Damage caused to something else than the product itself.

b) Damage or loss resulting during transportation, storage or handling after the date of supply.

c) Phenomenon unforeseeable in the state of the technology as of the supply date.

d) Damage caused by natural or unnatural events such as fire, earthquake, flood, or conflicts beyond our control.

+86-0755-29898410 +86-0755-29898460

+86-0755-29898410 +86-0755-29898460  ron@xaori.net

ron@xaori.net