In the deviation correction system device, the deviation correction light curtain sensor is a very important part of the whole equipment, which can effectively detect the strip edge, centering detection, real-time width detection and other information. The function of the deflection correction light curtain sensor is to detect the strip position. By measuring the horizontal position and offset of the strip, a specific program is used to control the drive device to drive the deflection correction roller to swing in the response direction at a certain speed to achieve the correction of the strip horizontal position in the middle.

The correction light curtain can be applied to the centering and correction measurement of cloth, steel strip, corrugated paper, film and other strips. The deviation correction light curtain is generally installed on the left and right sides of the conveyor belt, up and down, to play the role of detecting the deviation of the conveyor belt. Of course, according to the on-site use, the installation method will be slightly different in different parts.

There are two detection methods:

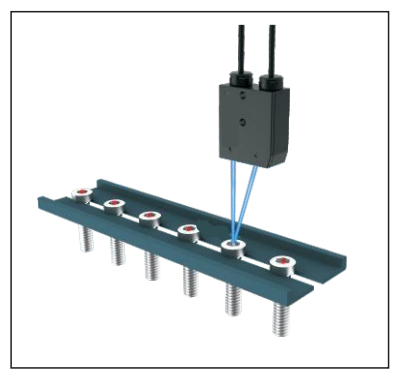

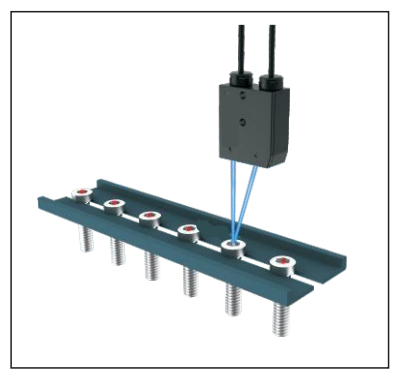

Single side detection mode: use a set of light curtains to detect an edge, and output a group of detection signals (without acrylic tube) to achieve deviation correction;

Bilateral detection mode: use a set of light curtains on both sides to detect the two sides at the same time to achieve deviation correction and unified output signal. It can also conduct real-time width measurement, hole detection and edge detection for the strip.

Main features of Pinto polarization correction screen:

1. It can be widely used in printing and packaging, paper making, film, weaving workshop and other industries that need to control the trimming.

2. Pinto's deflection correction light curtain has a solid structure, which can not only perform unilateral correction, but also bilateral correction, as well as centering correction, width measurement, hole detection and other functions.

3. Flexible installation and positioning components for deviation correction can be quickly and easily installed on various supporting deviation correction devices and tension controllers.

4. It has a control range of 80-3880mm and supports customization of different lengths.

5. It can be detected over a long distance and is easy to align.

6. With RS485 or RS232 communication function, it can communicate with the upper computer through standard MODBUS protocol. Support analog current output mode and analog voltage output mode;

7. High detection accuracy, optical axis spacing of 1.25 mm, 2.5 mm, 5 mm, 10 mm, can be used for high-precision detection and measurement.

8. Short response time, can be used for high speed running machines;

9. Strong anti-interference ability, good anti-interference ability to electromagnetic signal, stroboscopic signal, welding arc light and surrounding light sources;

10. Applicable temperature of conventional grating process: - 20 - ° C-70 - ° C. For the cloth industry, electronic original devices with higher temperature resistance are introduced, which are applicable to - 20 - ° C-90 - ° C (special needs need to be explained to the salesperson).

+86-0755-29898410 +86-0755-29898460

+86-0755-29898410 +86-0755-29898460  ron@xaori.net

ron@xaori.net