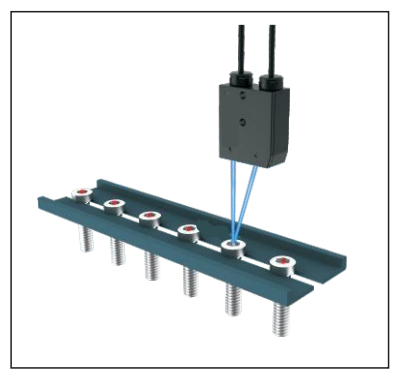

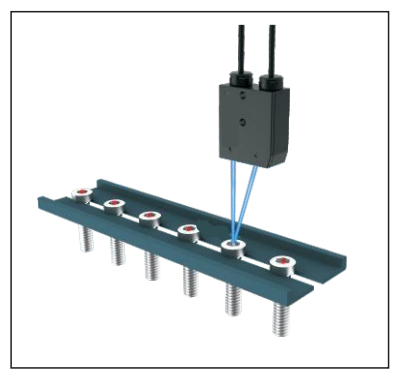

For punching machines, presses, cutting machines, metal cutting machines, stamping die production lines and other equipment with certain risk factors, once a safety incident occurs, it will cause irreparable damage to the company and itself. The installation of grating can effectively prevent and avoid dangerous safety accidents. As a result, technical engineers in foundries are paying more and more attention to the installation and application of safety light grids.

Safety light grids are suitable for various industrial production equipment. When installing the safety barrier, be sure to install it in accordance with the installation process to ensure the normal operation and service life of the safety barrier, and reasonably improve the work efficiency. Here are some tips for installing safety gratings. After learning, the efficiency and service life of the safety light grid can be improved.

1. According to the type of mechanical equipment and maintenance regulations, select the safety grating suitable for the model and specification, and reasonably maintain the safety of personnel.

2. According to the regulations of machinery and equipment, personnel's operating process methods and safety barrier model specifications, the appropriate installation position is clearly defined to prevent inappropriate installation positions from damaging productivity.

3. Strictly follow the safety grating product manual to start the installation. The general product manual will begin explaining the assembly of the product and support frame. It will be more convenient to refer to the installation instructions.

+86-0755-29898410 +86-0755-29898460

+86-0755-29898410 +86-0755-29898460  ron@xaori.net

ron@xaori.net