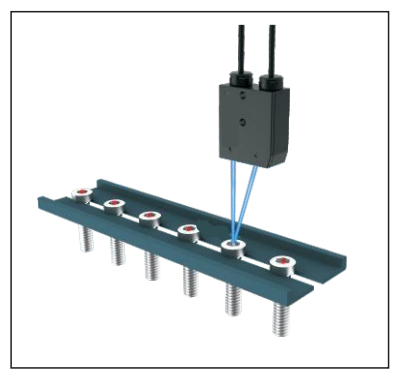

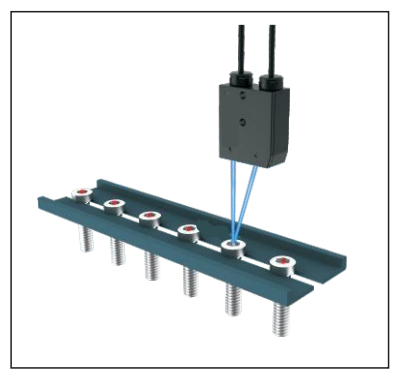

In a modern chemical plant, people and machines work together. On some potentially dangerous mechanical equipment, such as stamping machines, shearing equipment, metal cutting equipment, automatic assembly lines, automatic welding lines, mechanical conveying and handling equipment, and dangerous areas (toxic, high-pressure, high temperature, etc.), it is easy to cause personal injury to operators. Safety grating is an advanced technology to protect workers around various dangerous machinery and equipment. Compared with traditional safety measures, such as mechanical fences, sliding doors, pull back restrictions, etc., the safety grating is more free and flexible, and can reduce operator fatigue. By reasonably reducing the need for physical protection, security gratings simplify routine tasks such as equipment installation, maintenance, and repair.

One side of the light curtain is equipped with multiple infrared transmitting tubes at equal intervals, and the other side is equipped with corresponding infrared receiving tubes of the same number and arrangement. Each infrared transmitting tube is equipped with a corresponding infrared receiving tube, which is installed on the same straight line. When there is no obstacle between the infrared transmitting tube and the infrared receiving tube on the same straight line, the modulated signal (optical signal) sent by the infrared transmitting tube can reach the infrared receiving tube smoothly. After the infrared receiving tube receives the modulation signal, the corresponding internal circuit outputs a low level. In the case of obstacles, the modulation signal (optical signal) sent by the infrared transmitting tube cannot reach the infrared receiving tube smoothly. At this time, the infrared receiving tube cannot receive the modulation signal, and the corresponding internal circuit outputs a high level. When there is no object passing through the light curtain, all modulated signals (optical signals) sent by the infrared transmitting tubes can smoothly reach the corresponding infrared receiving tubes on the other side, so that all internal circuits can output low levels. In this way, the information about the existence of an object can be detected by analyzing the state of the internal circuit.

In practical application, the safety grating controller does not need a controller, but only a transmitter and receiver. When in use, it is connected through an aviation plug socket or cable. The output can be directly connected to external relays or various computer digital interfaces.

+86-0755-29898410 +86-0755-29898460

+86-0755-29898410 +86-0755-29898460  ron@xaori.net

ron@xaori.net